Welcome to Kaifeng Ruike Valve Co., Ltd.

Categories

Contact

E-mail :

rkvalve@vip.163.com

Tel:

86-371-27565515

Address:

West section of Fuyuan Road,Yushi County Industrial Clustering Zone

DN500 bidirectional metal hard seal butterfly valve

Categories:

Butterfly Valve

Product Model:

Calibre Range:

Pressure Rating:

Operating Temperature.

Main Body Material:

Connection Method:

Mode of Operation:

Application Industry:

Product Details

Product structure

Multi-level metal hard seal butterfly valve series products, our newly developed long life, energy-saving high-performance butterfly valve. Its structure adopts three-dimensional eccentric principle design, the valve seat adopts multi-level structure compatible with hard and soft sealing, exquisite processing, advanced technology. This product consists of valve body, butterfly plate, multi-level valve seat, valve stem, transmission mechanism and other major components.

Characteristic

As this product butterfly valve adopts three-dimensional eccentric principle design, the space movement trajectory of the sealing surface is idealized, no friction between the sealing surface and no interference between the moving parts, and the sealing materials are properly selected according to the requirements of different working conditions, so that the sealing, corrosion resistance, high temperature resistance, and abrasion resistance of the butterfly valve are reliably guaranteed. Its main features are as follows:

1. Small force distance after opening, flexible and convenient, labor-saving and energy-saving;

2. Three-dimensional eccentric structure, so that the butterfly plate is tighter and tighter, and its sealing performance is reliable;

3. High-pressure resistance, corrosion resistance, long service life and so on. Resistant to abrasion, long service life, etc.

Blueprint

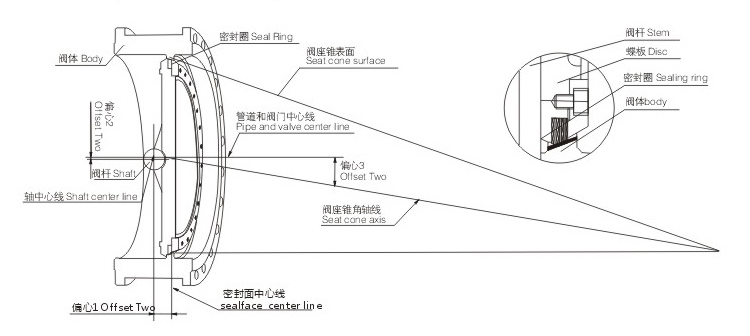

The Triple offset Geometry

1.The first eccentric, shaft deviated from the centerline of sealing face.

2.The second eccentric shaft deviated from the centerline of pipe and valve.

3.The third eccentric. the distinctive included angle between oblique taper angle of eccentric seat and centerline of pipe,thus making the seat completely disengaged from the sealing ring during the whole process of open and close.This structure not only uses cam effect, but also eliminatesthe possibility of abrasion and le akage.

The zero leakage of ourtriple eccentric butterfly valve is implemented by the composite stainless steel sealing ring mounted on the disc.

Zero leakage isimplemented by the elastic sealing ring mounted on the disc.The elasticity of sealing ring(see fig.Right) is produced by its radial compression and flexibility.The contact surface between the sealing ring and seat is an oblique cone.The contact angle between them gives slight wedge effect ,making the sealing ring producng flexibility and radial compression.The even contact between the seat and sealing ring, andthe closest cutoff bythe lowest torque.The elasticity produced by the torque makes the valve dosely cut off regardless of the flow direction or pressure of medium.

Parameters

Main technology parameter

|

Nominaldiameter |

DN(mm) |

50~1600 |

50~500 |

||||

|

Nominal pressure |

PN(MPa) |

0.6 |

1.0 |

1.6 |

2.5 |

4.0 |

|

|

Test pressurePs(MPa) |

Shell test |

0.9 |

1.5 |

2.4 |

3.75 |

6.0 |

|

|

Sealtest |

0.66 |

1.1 |

1.76 |

2.75 |

4.4 |

||

|

Leakage |

<0.1×DNmm³/s( accordwith GB/T13927-92 standard) |

||||||

|

Appropriate temperatuer |

Carbon steel:-29℃~350℃ Stainlesssteel:-40℃~600℃ |

||||||

|

Appropriate medium |

Air,water,steam,coal gas,oil and acid,alkali,salt corrosive medium and so on. |

||||||

|

Drive modality |

Worm worm wheel drive,gasdrive,electric drive. |

||||||

Material for main parts

|

Parts name |

Material |

|

Body |

Weld the piece,Cast steel,stainless steel,alloy stee |

|

Disc |

Weld the piece,Cast steel,Alloy steel,stainless steel |

|

Seal ring |

Stainless steel andhigh temperature resistant asbestos composed of multiplelayers |

|

Stem |

2Cr13、1Cr13 Stainless steel,Cr.Mo.Steel |

|

Axletree |

Aluminum bronze ZG00Cr18Ni10,304 nitrification |

|

Packing |

Flexible graphite |

Key words:

Butterfly Valve

Previous:

Company Information

Kaifeng Ruike Valve Co., Ltd. has developed into a joint-stock enterprise integrating valve research, development, production and sales. Founded in 2011, the company covers an area of 52,000 square metres. There are more than 136 employees, 45 technicians of various types, including 4 professor-level senior engineers.

The company now has CNC machining centres, CNC machine tools, large vertical lathes, large boring machines, CNC milling machines, automatic welding machines and other sophisticated machining equipment, and high-performance valve testing equipment more than 100 sets (sets). Set up semi-finished goods warehouse, finished goods warehouse and so on.

FAQ

Do you accept custom design on size?

Yes, if the size is reasonable.

Do you provide free sample?

Free sample is OK for us.

Transportation

Transported by DHL, UPS, EMS, FEDEX, SF, by Air, by Sea.

Payment

T/T, L/C, OA, D/P, D/A.

After-sales service

18 months year warranty for all kinds of products.

As an experienced manufacturer, you can rest assured of the quality and sales service.

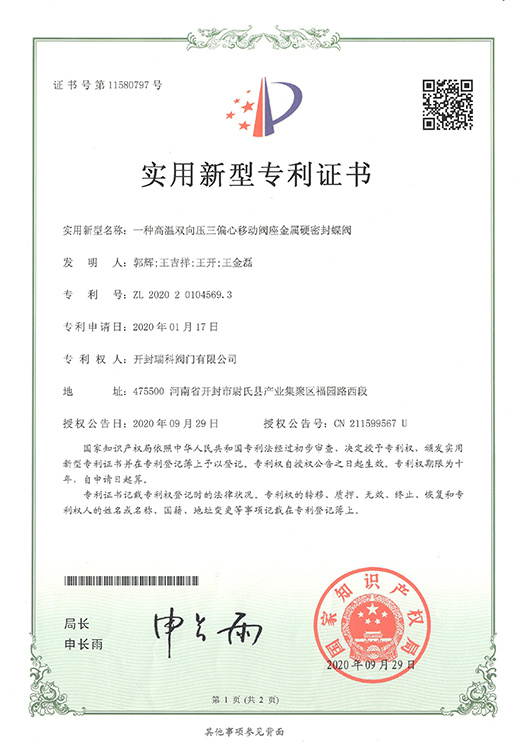

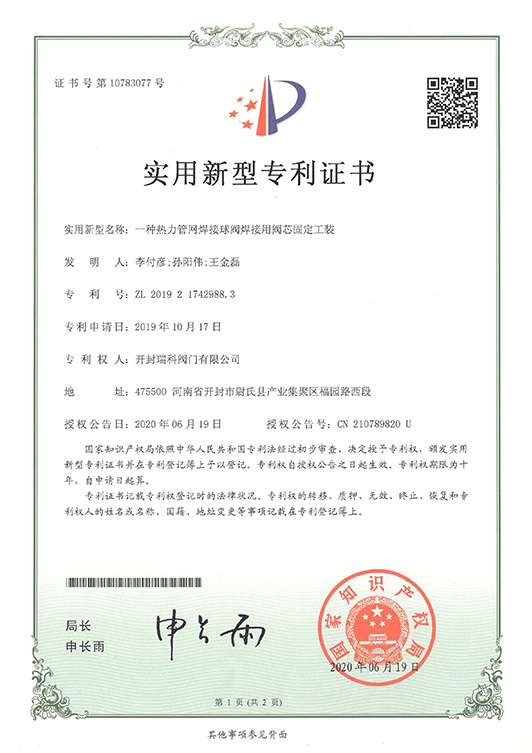

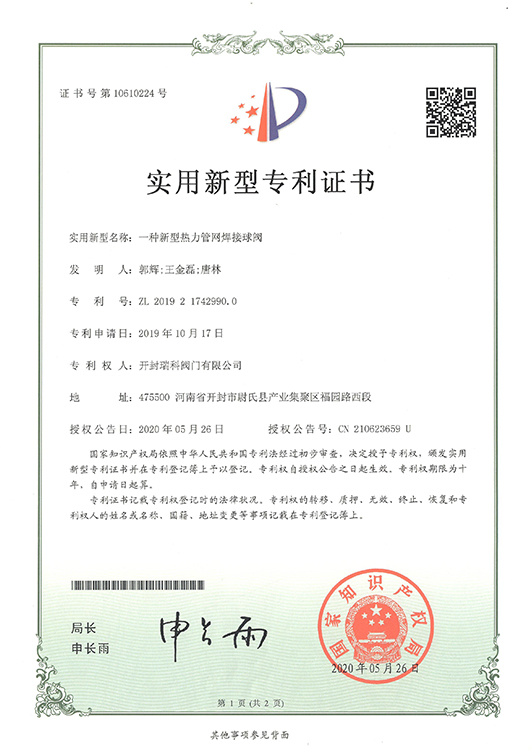

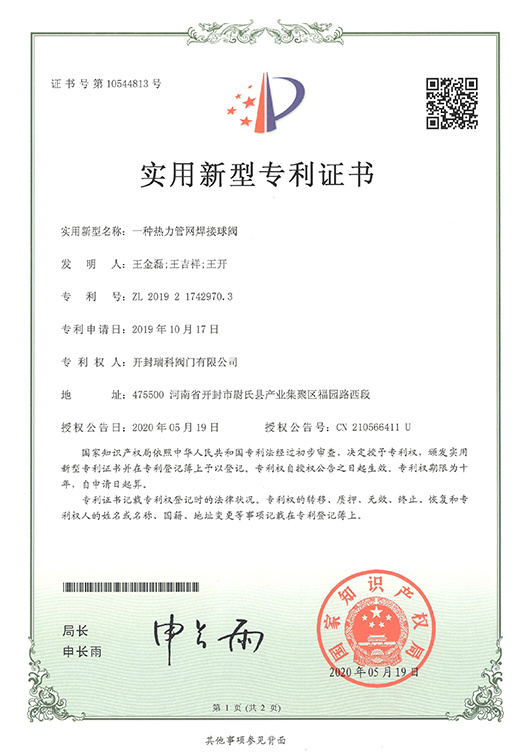

What certificates will you provide ?

We can provide CE/ ISO / WRAS.

Related Products

API6D cylindrical fixed flange ball valve

API6D cylindrical fixed full-welded underground ball valve

API6D Ball Type Fixed Full Welding Ball Valve

API6D Cylindrical Fully Welded Fixed Ball Valve