Welcome to Kaifeng Ruike Valve Co., Ltd.

Categories

Contact

E-mail :

rkvalve@vip.163.com

Tel:

86-371-27565515

Address:

West section of Fuyuan Road,Yushi County Industrial Clustering Zone

DN700 Barrel shaped fixed fully welded ball valve

Categories:

Ball Valve

Product Model:

DN700

Calibre Range:

DN1600mm;

Pressure Rating:

8Mpa;

Operating Temperature.

-29℃~200°C

Main Body Material:

Connection Method:

Mode of Operation:

Application Industry:

Product Details

Ruike welded ball valves are widely used in heating lines, municipal construction, city gas and other industrial pipelines, its main function is to cut off or connect the pipeline in the fluid channel, its opening and closing parts around the vertical center line of the valve body for the rotary 90 ° movement, clockwise closed, counterclockwise open, the valve open and close quickly and flexibly, the ball valve is relatively small in size, light in weight, simple in structure, easy to install and maintain. The ball valve is relatively small, light weight, simple structure, easy to install and maintain.

Ruike company welded ball valves do not have the function of regulating the flow of pipeline, prohibited as a control valve. The flow characteristics of the ball valve in the valve open, close the stage for the linear characteristics, in the middle of the opening degree of time for the equal percentage characteristics.

Welded ball valves from the structural form of floating ball valves and fixed ball valves, are my company's mature products, according to the technical specifications of the response to the requirements of the company's valve design, manufacturing experience, after many years of customer use, proved Ruike company welded ball valve product performance is reliable.

Floating ball structure: floating ball valve ball in the valve body is floating, under the pressure of the fluid medium, the ball is tightly pressed to the outlet end of the sealing seat, forming a valve seal, this structure of the ball valve is characterized by a simple structure, good sealing performance.

Fixed ball structure: the fixed structure of the ball with upper and lower rotary axis, the lower part of the ball inlaid bearings, fixed by the lower stem, the upper part of the stem and the upper stem is connected, the ball can only be rotated along the axis of the valve channel vertical movement, not like floating ball valves as the ball can be moved to the side, so the fixed ball valves work, the pressure of the fluid in front of the valve and the spring force to push the valve seat tightly pressed to the ball, to form a reliable prevalent valve sealing! Fixed ball valves have DBB function, that is, the valve can simultaneously cut off the pipeline upstream and downstream of the media, the valve sealing is safe and reliable.

Product Characteristics

• Small flow resistance coefficient

Ball valves in the nominal flow of pressure loss is the smallest of all valves, equivalent to the same length of the pipe flow resistance coefficient, almost zero; my company's reduction of ball valves after fluid analysis and theoretical calculations, the flow path design to maximize the valve's ability to improve the circulation, reduce the reduction of the part of the resulting flow resistance.

• Bidirectional seal

Ball valve is not affected by the direction of the fluid medium, any end of the valve can be used as the upstream end, fixed ball valve can simultaneously cut off the fluid medium from upstream and downstream.

• Good sealing performance

Double-seat bidirectional sealing, seat seal for VITONB + non-metallic polymers for different pressure levels + hard seal composition, to ensure that the ball valve in different pressure differential can be achieved bubble level sealing (both zero leakage), sealing is safe and reliable.

• Long service life

The sealing surface of non-metallic material has good lubricity, and ball friction and wear is small, the structure of multi-stage sealing, coupled with the role of the spring preload, so that the sealing is safe and reliable, thus improving the service life of the ball valve.

Product Installation

1, the pipeline connected with the valve should be cleaned to avoid iron filings, mud, welding slag and other debris to damage the valve sealing surface.

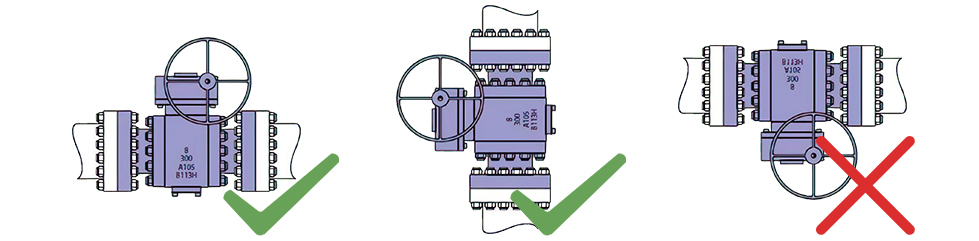

2, this series of ball valves can be installed in any position, any end of the valve can be used as the upstream end, the valve can be installed horizontally and vertically, but the valve is prohibited from being installed upside down to prevent stem corrosion;.

3, the installation of the valve should be kept in the fully open position (factory has been adjusted in place), otherwise it may lead to damage to the valve; Warning: Do not place the valve in a half-open and half-closed state.

4, the center of the valve and piping center and pipeline consistent before welding installation.

5, welding connection should be in accordance with the welding process evaluation qualified welding process construction, installation welding to prevent welding slag, welding beans into the valve cavity, damage to the sealing surface. Installation of the valve should be in the fully open position, otherwise it may lead to damage to the valve. WARNING:For butt-welding connection end ball valves, please do not install the valve in the closed position. If the valve must be kept in the closed position, grease the exposed ball surface, which will protect the ball from being damaged by spattered weld slag.

6, in the preheating, welding, thermal stress relief, 75mm away from the weld outside of any point on the valve body temperature can not exceed 200 ° ° C, please use a thermometer to check the temperature.

7, the valve installation process should ensure that the valve body cavity clean, to prevent debris from entering the body cavity.

8, the welding end of the valve installation should be visually inspected after welding or non-destructive examination to confirm that no cracks, weld tumor, biting edge and other harmful defects, should be required to carry out non-destructive flaw detection of the weld:.

9, there is a drive device valve, electrical, pneumatic, hydraulic piping should be connected according to the instructions wiring diagram or piping diagram, before connecting to confirm the correctness of the line; valves factory open and close position has been adjusted in place, do not have to re-adjust.

10, buried pipeline valve actuators can not be immersed in water or mud, so as to avoid damage to the actuator.

Tip: When the valve is unavoidably immersed in water or mud for a long time, the customer should inform the manufacturer in advance, so that the manufacturer to come up with countermeasures in advance.

11, large diameter welded ball valve installation, the weight of the valve can not all act on the pipeline, should set up a fixed pier or bracket for support.

12, there are external insulation requirements of the valve should be passed into the medium before the completion of the construction of the protective layer.

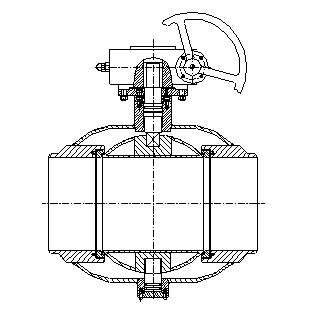

Blueprint

Design parameters

Design and manufacture:GB/T12237, GB/T37827, GB/T12224, ASME B16.34

Inspection and testing: GB/T13927, JB/T9092, ISO 5208

Fire test: GB/T26479, API 6FA, API 607

Pressure level: 8Mpapa.

Diameter range: DN1600mm.

Applicable medium: water, gas, oil, etc.; and

Applicable temperature:-29℃~200°C.

Parameters

Material details of major components

|

Part name |

Standard material |

Stainless steel material |

Forging material |

|

Valve body |

20# |

304 |

A105 |

|

Bonnet |

20# |

304 |

A105 |

|

sphere |

304 |

F304 |

F304 |

|

Seat |

A105+ENP |

304 |

A105+ENP |

|

Seat seal rings |

RPTFE |

RPTFE |

RPTFE |

|

Stem |

20CR13 |

304SS |

20CR13 |

|

Stuffing box |

20# |

304 |

A105 |

|

spring |

INCONEL X-750 |

INCONELX-750 |

INCONEL X-750 |

|

pivot |

20CR13 |

304SS |

20CR13 |

|

Upper and lower diameters |

20# |

304 |

A105 |

|

sliding bearing |

304+MOS2+PTFE |

304+MOS2+PTFE |

304+MOS2+PTFE |

|

O-rings |

Viton |

Viton |

Viton |

|

Anti-static device |

304SS |

304SS |

304SS |

FAULTS AND TROUBLESHOOTING

|

Fault |

Cause of the failure |

Exclusion Method |

|

The operation is jammed |

1. Damage to the driving device 2. The installation of the packing culvert is tilted 3. The valve seat area is blocked 4. The valve stem is bent and bitten |

1. Maintenance and repair of the driving device 2. Loosen the packing culvert screws and re-calibrate and install the packing culvert 3. Turn the handwheel and switch it on and off a few times 4. Calibrate or replace the valve stem (please contact our company) |

|

Leaking valve seat |

1. The valve is not completely closed 2. The setting of the limiter of the driving device is incorrect 3. The sealing surface is damaged due to abrasion |

1. Operate the valve to the fully closed position 2. Appropriately adjust the limiter of the driving device 3. Please contact the company for maintenance |

|

Stem leakage |

1. The stem seal is damaged 2. The valve stem is damaged |

1. Replace the stem packing 2. Repair or replace the valve stem (please contact us) |

Key words:

Ball Valve

Company Information

Kaifeng Ruike Valve Co., Ltd. has developed into a joint-stock enterprise integrating valve research, development, production and sales. Founded in 2011, the company covers an area of 52,000 square metres. There are more than 136 employees, 45 technicians of various types, including 4 professor-level senior engineers.

The company now has CNC machining centres, CNC machine tools, large vertical lathes, large boring machines, CNC milling machines, automatic welding machines and other sophisticated machining equipment, and high-performance valve testing equipment more than 100 sets (sets). Set up semi-finished goods warehouse, finished goods warehouse and so on.

FAQ

Do you accept custom design on size?

Yes, if the size is reasonable.

Do you provide free sample?

Free sample is OK for us.

Transportation

Transported by DHL, UPS, EMS, FEDEX, SF, by Air, by Sea.

Payment

T/T, L/C, OA, D/P, D/A.

After-sales service

18 months year warranty for all kinds of products.

As an experienced manufacturer, you can rest assured of the quality and sales service.

What certificates will you provide ?

We can provide CE/ ISO / WRAS.

Related Products

API6D cylindrical fixed flange ball valve

API6D cylindrical fixed full-welded underground ball valve

API6D Ball Type Fixed Full Welding Ball Valve

API6D Cylindrical Fully Welded Fixed Ball Valve