Welcome to Kaifeng Ruike Valve Co., Ltd.

Categories

Contact

E-mail :

rkvalve@vip.163.com

Tel:

86-371-27565515

Address:

West section of Fuyuan Road,Yushi County Industrial Clustering Zone

DN300 hard seal ball valve

Categories:

Ball Valve

Product Model:

DN300

Calibre Range:

NPS1/2~24(DN15~DN600);

Pressure Rating:

150Lb~2500Lb(1.6MPa~42.0MPa);

Operating Temperature.

-29℃~540℃;

Main Body Material:

carbon steel, austenitic stainless steel, two-way stainless steel and so on;

Connection Method:

supersonic spraying tungsten carbide, chromium carbide, spray welding nickel-based alloy, surfacing cobalt-based alloy, etc;

Mode of Operation:

handle, worm gear box, electric, pneumatic, hydraulic, gas-liquid linkage, electro-hydraulic linkage.

Application Industry:

Product Details

Our company is committed to the study of metal wear-resistant ball valves, in-depth customer working conditions on-site to understand the use of valves, absorb and digest the design concepts of famous foreign manufacturers to form their own structural design, has a strong working conditions targeted.

My company metal hard seal ball valve from the structure of the form is divided into two forms of floating ball valves and fixed ball valves, floating ball valves are two-piece cast steel floating ball valves and two-piece forged steel floating ball valves, fixed ball valves are divided into two-piece cast steel fixed ball valves and three-piece forged steel fixed ball valves.

Kaifeng Ruike hard seal ball valve can meet the high temperature, high pressure and particulate media and other harsh conditions, with sealing safety and reliability, long service life, easy to operate and so on, widely used in a variety of equipment and pipeline, especially in high temperature, high pressure, abrasion, corrosion, crystallization, coking, scouring, high-frequency action and other harsh conditions, the hard seal ball valve is the best choice.

Hard seal ball valve technical parameters

Design standards: API6D, API608, GB/T21385, etc;

Inspection standards: API598, ASME B16.104, JB/T9092;

Flange connection: ASME B16.5, HG, GB and so on;

Structure length: ASME B16.10, GB/T12221, etc.;

Pressure level: 150Lb~2500Lb (1.6MPa~42.0MPa);

Range of diameter: NPS1/2~24 (DN15~DN600);

Applicable temperature: -29℃~540℃;

Main material: carbon steel, austenitic stainless steel, two-way stainless steel and so on;

Seal surface hardening methods: supersonic spraying tungsten carbide, chromium carbide, spray welding nickel-based alloy, surfacing cobalt-based alloy, etc;

Operating devices: handle, worm gear box, electric, pneumatic, hydraulic, gas-liquid linkage, electro-hydraulic linkage.

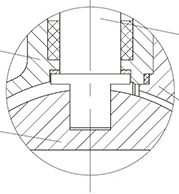

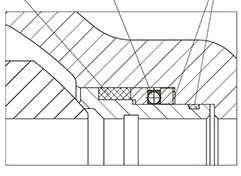

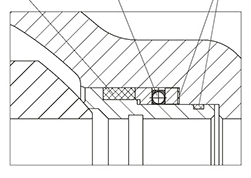

Blueprint

Hard seal ball valve design features

♦ Bidirectional sealing

Hard seal ball valve adopts double seats, both seats can independently cut off the fluid at the inlet end to realize double blocking function. Kaifeng Ruike hard seal ball valve seat sealing surface is wide, so that the valve seat can withstand enough sealing specific pressure, ball and seat research, the sealing vice match is high, to ensure reliable sealing.

♦ Large torque actuator

The output torque of the actuator is more than 1.5 times of the operating torque of the valve under the maximum differential pressure, and its transmission chain is designed to be at least 2 times of the maximum torque of the valve, so that the valve can maintain the stability of the action in the case of general overpressure.

♦ Stem anti-pushing out design

The valve stem is designed as a T-type structure, with inverted mounting and upper sealing, which can prevent the valve stem from flushing out under the medium pressure and ensure the sealing.

♦ Fire-retardant and anti-static design

Metal hard seal ball valve sealing components are made of metal or graphite material, can realize unconditional fire safety. The valve body, ball, and stem maintain metal contact with each other, forming a conductive path for safety and anti-static design.

♦ Self-cleaning scraper seat design

The valve seat adopts “scraping” design, when the valve is switching action, it will clean the spherical surface to avoid coking and fouling of particles in the sealing vice, to ensure the reliability of sealing and prolong the service life of the valve.

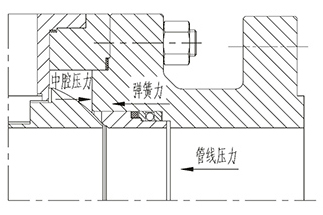

♦ Self-discharge design of the center cavity

When the pressure in the cavity of the valve is greater than the preload of the seat spring and the pipeline medium pressure, the pressure in the cavity will push the seat to both sides of the pipeline, and the overload pressure in the cavity will be released into the pipeline automatically to ensure the safety of valve operation.

♦ Low leakage packing design

Metal hard seal ball valves are mostly used in harsh working conditions, in order to improve the overall sealing performance of the valve, the company's hard seal ball valves use low leakage packing, packing is composed of v-type sealing layer, graphite packing is molded to ensure that the stem part of the sealing performance.

♦ Dust-proof spring structure

Graphite ring is added after the adjusting pad to prevent particles or dust from entering the spring under the bad working condition of the medium containing particles to ensure the long-term use of the spring.

Parameters

Coating materials

Coating materials must be wear-resistant, corrosion-resistant, impact resistant, high bonding force, low porosity and low friction rate, while also taking into account the properties of different base material materials.

Kaifeng Ruike has standardized the coating materials for different working condition requirements.

|

serial number |

Spray materials |

Coating hardness |

Coating thickness |

Spraying method |

Operating temperature |

Substrate material |

|

1 |

Cr-Ni-Si-B |

57-63(HRC) |

400-600um |

Thermal spraying |

<650°C |

SS、F51 |

|

2 |

Cr-Ni-WC-Co |

60-65(HRC) |

400-600um |

Thermal spraying |

<650°C |

SS、F51 |

|

3 |

W-C-Co |

68-74(HRC) |

150-250um |

Supersonic spraying |

<450°C |

Cr13、SS、F51 |

|

4 |

W-C-Co-Cr |

68-72(HRC) |

150-250um |

Supersonic spraying |

<470°C |

Cr13、Ss、F51 |

|

5 |

Cr-C-Ni-Cr |

53-57(HRC) |

150-250um |

Supersonic spraying |

<850°C |

Cr13、SS、F51 |

|

6 |

W-Cr-Co-N |

50-55(HRC) |

150-250um |

Supersonic spraying |

<650°C |

Cr13、SS、F51 |

Seal surface hardening treatment can be obtained after wear resistance, erosion resistance, corrosion resistance and other characteristics, a variety of hardening treatment can be selected according to different working conditions.

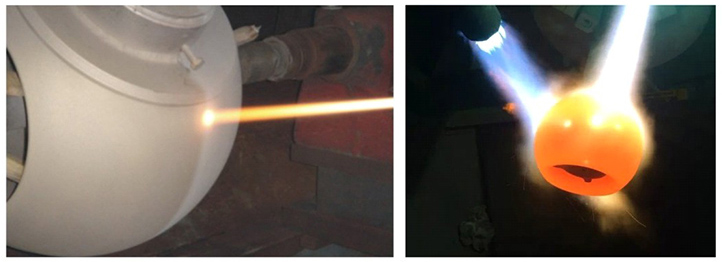

• HVOF supersonic spraying: supersonic flame powder spraying tungsten carbide, chromium carbide, etc., hardened coatings with low porosity, bonding force greater than 7OMPa, hardness up to HRC8o, hardened layer thickness of 150 ~ 250um.

• High-temperature spray welding: oxyacetylene flame spraying alloy powder, in the use of combustion flame will be a spray melt or spray layer for the second remelting, so that the spray layer and the substrate material is a metallurgical bonding state, the bonding force of up to 400MPa, hardness of up to HRC65, hardened layer thickness of 400 ~ 6ooum, the thickest up to 1.5mm.

Surfacing: sealing surface surfacing cobalt-based alloy, hardness up to HRC44, thickness of surfacing layer ≥ 2mm.

• Integral sintered tungsten carbide: the seals are made of alloy powder sintered at high temperature and processed by grinding, with low porosity and hardness up to HRA90, with high hardness and wear resistance.

Key words:

Ball Valve

Previous:

Company Information

Kaifeng Ruike Valve Co., Ltd. has developed into a joint-stock enterprise integrating valve research, development, production and sales. Founded in 2011, the company covers an area of 52,000 square metres. There are more than 136 employees, 45 technicians of various types, including 4 professor-level senior engineers.

The company now has CNC machining centres, CNC machine tools, large vertical lathes, large boring machines, CNC milling machines, automatic welding machines and other sophisticated machining equipment, and high-performance valve testing equipment more than 100 sets (sets). Set up semi-finished goods warehouse, finished goods warehouse and so on.

FAQ

Do you accept custom design on size?

Yes, if the size is reasonable.

Do you provide free sample?

Free sample is OK for us.

Transportation

Transported by DHL, UPS, EMS, FEDEX, SF, by Air, by Sea.

Payment

T/T, L/C, OA, D/P, D/A.

After-sales service

18 months year warranty for all kinds of products.

As an experienced manufacturer, you can rest assured of the quality and sales service.

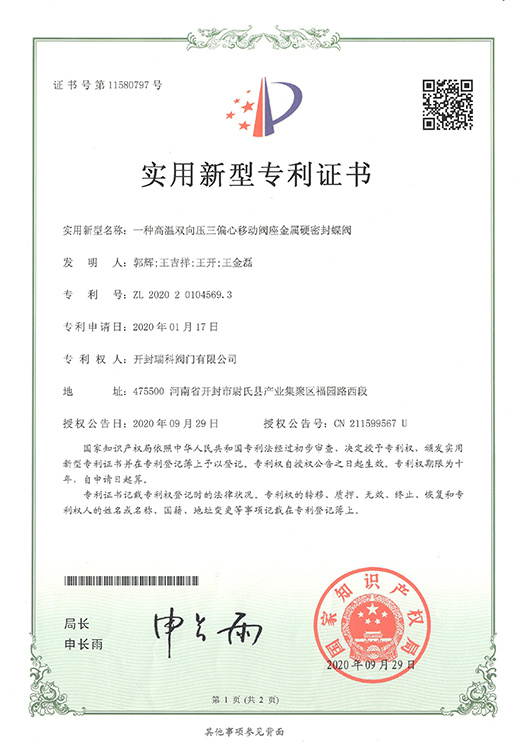

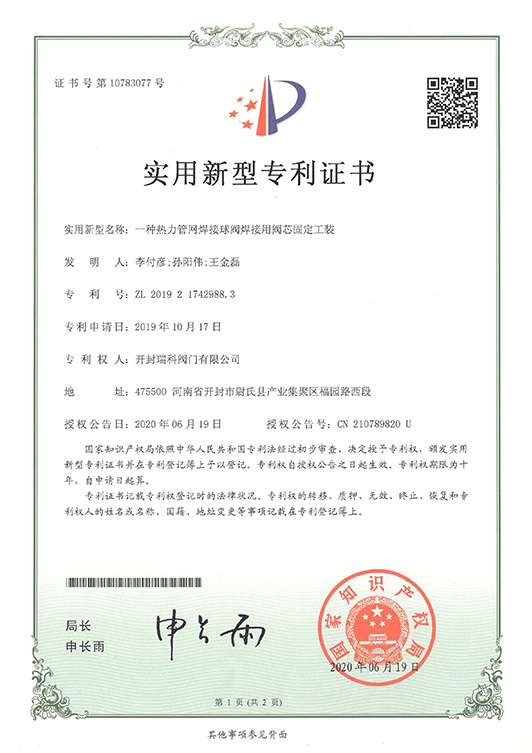

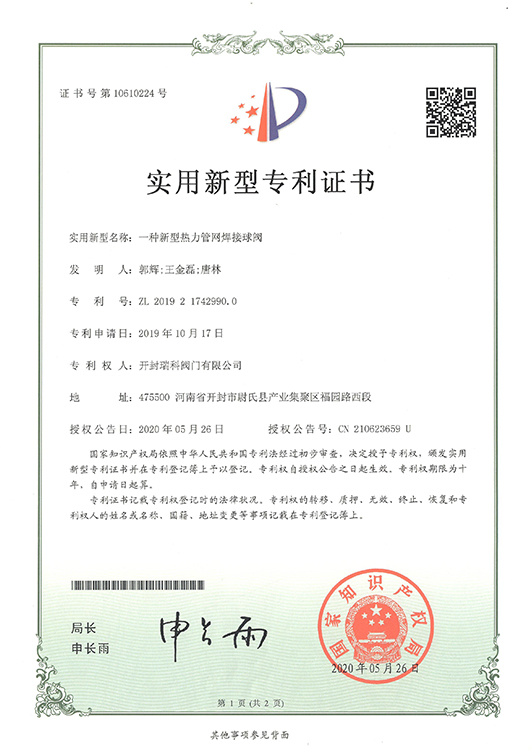

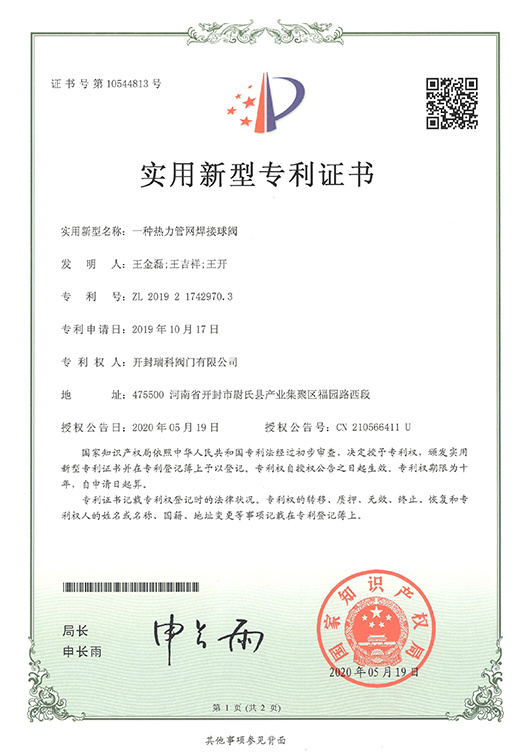

What certificates will you provide ?

We can provide CE/ ISO / WRAS.

Related Products

API6D cylindrical fixed flange ball valve

API6D cylindrical fixed full-welded underground ball valve

API6D Ball Type Fixed Full Welding Ball Valve

API6D Cylindrical Fully Welded Fixed Ball Valve